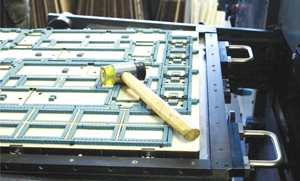

Die-cutting is a required process in the industrial production of packaging and corrugated cardboard. A good die-cut press achieves time savings for orders, less waste for set up and continuous work with the same precision in each shot and not least convenience in carrying out the process.

When precision finishing is a requirement for your packaging materials, we have the right technology as well as the expertise to get it done. Using world class die-cutter from the Swiss company BOBST that works with unmatched Swiss precision we are able to produce packages of any configuration that run on high speed packing lines.

We have 2 folding-gluing machines

1. Bobst Expertfold 110 computer control system for gluing HHS to 8 points of bonding.

- machine gives great flexibility, numerous modifications for gluing folding carton and corrugated board up to six points

- exceptional performance

- unsurpassed quality and accuracy of the folding and gluing

The machine has a modern system to adjust and save up to 75% of the time required for setup.

Ensure less waste thereby saving unnecessary costs.

- Built-in device for adjustment of the prepared products

- Perfect-quality folding and gluing throughout the entire machine tape

- Easily controlled speed

- unmistakably-charging and gluing of packaging with unusual shapes

2. Jgenberg Diana 105 system for gluing HHS to 6 points of bonding