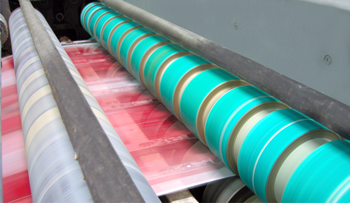

Apart from the conventional overprint varnish and UV overprint varnish that are applied by the inking unit of the printing press, we have also special coating units that enable us to apply aqueous and UV coatings. The major difference between the OP (overprint) varnish and the one applied by a coater is the thickness of the film and from that the achieved visual effect.

Moreover, we can now achieve the new finish called pseudo-embossing (or chemical emboss) which is used to create a contrast between textured (embossed) and gloss varnish. This embossing effect utilizes the reaction between a special UV overprint varnish and a UV clear coating varnish. The sections where both the OP varnish and the clear varnish are applied have an embossed look. The surface has a textured effect, appearing like water drops that have hardened. The sections where only clear varnish is applied have a normal UV high gloss. The appeal of this method is that different areas of the image stand out visually due to the contrast between clear and matte varnishes. The production advantage is that a spot varnish is possible without using a photopolymer plate because the image detail is determined by using an OP varnish. Therefore, this technique is a cost effective way to achieve stunning visual effect for you packaging.

We also have a laminating machine. Lamination is a process where transparent or colored foil is applied on a soft or hard surface. The laminate protects the image from scratch, water, UV rays and other harmful influences. This in most cases is a required process for the manufacture of packaging for the food industry, because among other things protects the package from oiling. The food processing film is consistent with the requirements for food contact. Depending on the intended use laminates with different thickness and color can be used.